Safety Policy vs Safety Manual: Understanding the Foundation of Workplace Safety

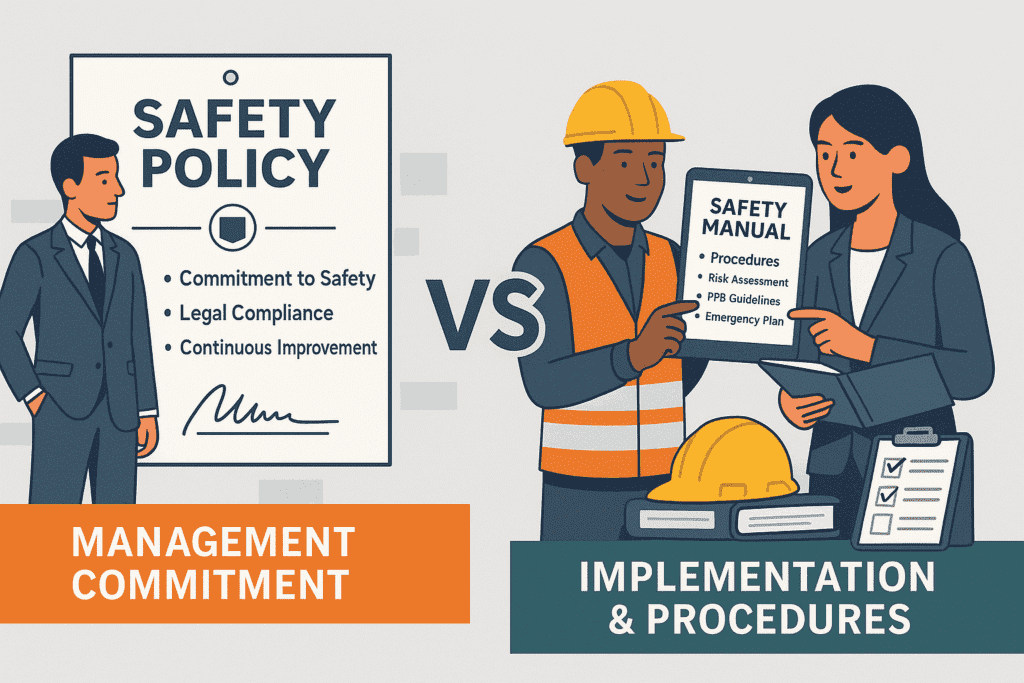

When building a strong safety culture in any organization, two documents stand at the foundation — the Safety Policy and the Safety Manual.

They might sound similar, but they serve very different purposes in shaping workplace safety systems.

In simple terms:

- A Safety Policy defines the commitment and intent of management towards safety.

- A Safety Manual explains the methods and procedures to achieve that commitment.

Let’s explore their definitions, purposes, contents, key differences, and why both are crucial for compliance and organizational success.

What is a Safety Policy?

Definition

A Safety Policy is a formal statement of an organization’s commitment to maintaining a safe and healthy workplace.

It outlines the company’s goals, responsibilities, and principles regarding occupational health and safety (OHS).

It’s often a short, high-level document signed by top management, communicating the organization’s dedication to safety and continuous improvement.

Purpose of a Safety Policy

- To demonstrate management commitment to safety.

- To define clear responsibilities for all employees.

- To ensure compliance with legal and regulatory requirements (e.g., OSHA, ISO 45001).

- To guide all safety decisions and actions within the company.

- To promote worker participation in maintaining safety.

Key Components of a Safety Policy

- Commitment Statement: Expresses management’s pledge to provide a safe workplace.

- Objectives: Outlines measurable safety goals (e.g., zero injuries, compliance targets).

- Responsibilities: Defines roles of management, supervisors, and employees.

- Legal Compliance: Ensures adherence to applicable laws and standards.

- Continuous Improvement: Encourages ongoing review and improvement.

Example of a Safety Policy Statement

“Our organization is committed to providing a safe and healthy workplace for all employees, contractors, and visitors. We aim to eliminate hazards, comply with all applicable laws, and continuously improve our occupational health and safety management system.”

What is a Safety Manual?

Definition

A Safety Manual is a detailed guidebook that describes the procedures, standards, and practices employees must follow to ensure workplace safety.

It is a comprehensive document used by all staff — from management to workers — to understand how safety is implemented, monitored, and maintained.

Purpose of a Safety Manual

- To provide step-by-step instructions on how to perform work safely.

- To describe company-specific safety procedures and protocols.

- To serve as a training and reference tool for employees.

- To ensure consistency in safety practices across departments.

- To maintain documentation for audits and inspections.

Key Components of a Safety Manual

- Introduction and Scope

- Roles and Responsibilities

- Hazard Identification and Risk Assessment (HIRA)

- Permit to Work System

- Emergency Procedures

- Incident Reporting and Investigation

- Personal Protective Equipment (PPE)

- Safety Training and Communication

- Safety Rules and Regulations

- Review and Update Procedures

Example of a Safety Manual Section

Hot Work Safety Procedure:

- Hot work permit must be obtained before starting.

- Fire extinguishers must be available within 5 meters.

- Fire watch must remain 30 minutes after completion.

- Gas cylinders must be stored upright and secured.

Key Differences Between Safety Policy and Safety Manual

| Aspect | Safety Policy | Safety Manual |

|---|---|---|

| Definition | A statement of intent and commitment to safety | A detailed guide describing how to achieve safety |

| Purpose | To express top management’s vision and principles | To provide procedures and instructions for implementation |

| Level of Detail | General and high-level | Detailed and operational |

| Audience | Employees, regulators, stakeholders | Workers, supervisors, and safety practitioners |

| Length | Short (1–2 pages) | Long and comprehensive (many pages) |

| Focus | “What” and “Why” | “How” and “When” |

| Issued By | Top management | Safety department or management representatives |

| Example | “We are committed to zero harm.” | “Wear a safety harness while working above 2 meters.” |

| Review Frequency | Annually or when major changes occur | Regularly (quarterly or as needed) |

Relationship Between the Safety Policy and Safety Manual

The Safety Policy and Safety Manual are interconnected:

- The policy sets the direction, and the manual provides the roadmap.

- The policy answers “What do we believe?” while the manual answers “How do we achieve it?”

- The manual is essentially the implementation tool of the policy.

Example:

If the Safety Policy states:

“We will prevent all injuries and incidents through effective hazard control.”

Then the Safety Manual will include:

- Risk assessment procedures.

- Safe work method statements (SWMS).

- Hazard reporting process.

Importance of Both Documents in Workplace Safety

1. Legal Compliance

Both documents are essential under safety management systems such as:

- ISO 45001:2018 (Occupational Health & Safety Management)

- OSHA Standards (General Duty Clause)

- ILO-OSH 2001 Guidelines

2. Communication and Awareness

The Safety Policy communicates management intent, while the Safety Manual provides detailed employee instructions — ensuring everyone understands their responsibilities.

3. Foundation for Safety Programs

Both form the basis for safety audits, training, and continuous improvement programs.

4. Supports Organizational Culture

A well-written safety policy sets the tone for leadership commitment, and the manual reinforces daily safety behavior.

Example Scenario

Construction Company

- Safety Policy: States a commitment to zero incidents and continuous safety training.

- Safety Manual: Includes safe operating procedures for scaffolding, lifting, excavation, and electrical work.

Manufacturing Industry

- Safety Policy: Focuses on providing safe machinery and reducing downtime.

- Safety Manual: Details lockout/tagout procedures, PPE usage, and machine guarding guidelines.

How to Develop a Safety Policy

- Consult management and employees.

- Define safety objectives aligned with business goals.

- Include compliance references to standards and laws.

- Assign responsibilities across levels.

- Get approval and signature from top management.

- Display the policy at visible workplace areas.

- Review annually or after major incidents.

How to Develop a Safety Manual

- Start with your Safety Policy as the foundation.

- Include all relevant procedures and controls.

- Organize content by department or hazard type.

- Add forms, checklists, and flowcharts.

- Review regularly for accuracy and compliance.

- Train employees on how to use the manual effectively.

Pro Tip: Use your safety manual as a live document — update it whenever there’s a new risk, technology, or regulation.

Integration with Safety Management Systems

Both documents play key roles in an integrated safety management system:

| ISO 45001 Clause | Document Role |

|---|---|

| 5.2 – OH&S Policy | Safety Policy |

| 7.5 – Documented Information | Safety Manual |

| 8.1 – Operational Planning & Control | Procedures within Safety Manual |

| 10.2 – Incident & Nonconformity | Reporting procedure (manual) |

Common Mistakes to Avoid

- Creating a generic safety policy without organizational relevance.

- Not updating the safety manual regularly.

- Using complex language instead of clear, practical terms.

- Treating documents as paperwork instead of active tools.

- Lack of employee awareness and access.

Summary Table: Safety Policy vs Safety Manual

| Parameter | Safety Policy | Safety Manual |

|---|---|---|

| Focus | Management’s commitment | Implementation and guidance |

| Content | Principles, responsibilities, objectives | Procedures, methods, instructions |

| Audience | Everyone in the organization | Workers and supervisors |

| Purpose | Communicate vision and compliance | Guide safe work practices |

| Example Document | 1-page policy statement | 100+ page procedure manual |

Conclusion

In summary, the Safety Policy defines what the organization stands for in terms of health and safety, while the Safety Manual explains how it achieves those standards in practice.

“A policy without a manual is just a promise — a manual without a policy is just a plan. Together, they create purpose.”

One provides direction, the other provides execution.

Together, they form the backbone of a robust safety management system that not only ensures compliance but also fosters a true culture of safety.

For checklist and templates visit The HSE Tools.

Construction Safety Checklist Generator – Complete Guide for Safety Professionals

Training Attendance Sheet Generator – Complete Guide for Safety Professionals

Safety Induction Checklist Generator – Complete Guide for Safety Professionals

Toolbox Talk Generator – Complete Guide for Safety Professionals

Permit-to-Work (PTW) Generator – Complete Guide for Safety Professionals

FAQs

Q1. Who writes the safety policy?

Usually written by top management with input from the safety officer or HSE team.

Q2. Who maintains the safety manual?

The safety department or HSE manager updates it regularly based on risk assessments and operational changes.

Q3. How often should the safety policy be reviewed?

At least once a year or after significant organizational changes.

Q4. Can the safety manual replace the policy?

No. The policy shows commitment; the manual provides the procedures — both are required.

Q5. Should every company have both?

Yes. Even small businesses need a clear policy and a simplified manual to ensure accountability and safety compliance.

Easy to understand it