Rigging Safety Quiz Ebook: Free Download

Introduction

Safety is paramount in rigging operations to prevent accidents, injuries, and fatalities. Our free Rigging Safety Quiz Ebook aims to educate individuals about rigging safety practices and procedures to ensure safe work environments. Let’s explore the key topics covered in this valuable resource.

Chapter 1: Understanding Rigging Safety

Hazards in Rigging Operations

- Fall Hazards: Working at heights increases the risk of falls and related injuries.

- Struck-By Hazards: Risks associated with being struck by falling objects or moving loads.

Importance of Safety Protocols

- Preventive Measures: Implementing safety protocols to mitigate risks and prevent accidents.

- Safety Culture: Fostering a culture of safety awareness and adherence to procedures among rigging personnel.

Chapter 2: Rigging Equipment and Inspection

Types of Rigging Equipment

- Slings and Shackles: Common rigging components used for lifting and securing loads.

- Hoists and Cranes: Machinery essential for lifting and moving heavy loads safely.

Proper Inspection and Maintenance

- Visual Inspection: Regularly inspecting rigging equipment for signs of wear, damage, or deterioration.

- Maintenance Procedures: Performing routine maintenance tasks to ensure equipment functionality and safety.

Chapter 3: Load Handling and Rigging Techniques

Proper Load Handling Practices

- Weight Limits: Adhering to weight limits specified for rigging equipment and load capacities.

- Center of Gravity: Understanding load distribution and center of gravity for safe lifting operations.

Safe Rigging Techniques

- Proper Rigging Configuration: Ensuring correct rigging setup and load attachment to prevent accidents.

- Communication: Establishing clear communication between rigging personnel to coordinate lifting operations safely.

Chapter 4: Rigging Safety Regulations and Standards

OSHA Regulations for Rigging

- General Industry Standard 1910.184: OSHA regulations addressing rigging safety requirements.

- Construction Industry Standard 1926.251: OSHA standards specific to rigging operations in the construction sector.

Industry Standards and Best Practices

- ANSI/ASSE Standards: American National Standards Institute (ANSI) guidelines for rigging safety practices.

- Industry Best Practices: Recommended practices and guidelines established by industry organizations.

Chapter 5: Risk Assessment and Hazard Identification

Techniques for Assessing Risks

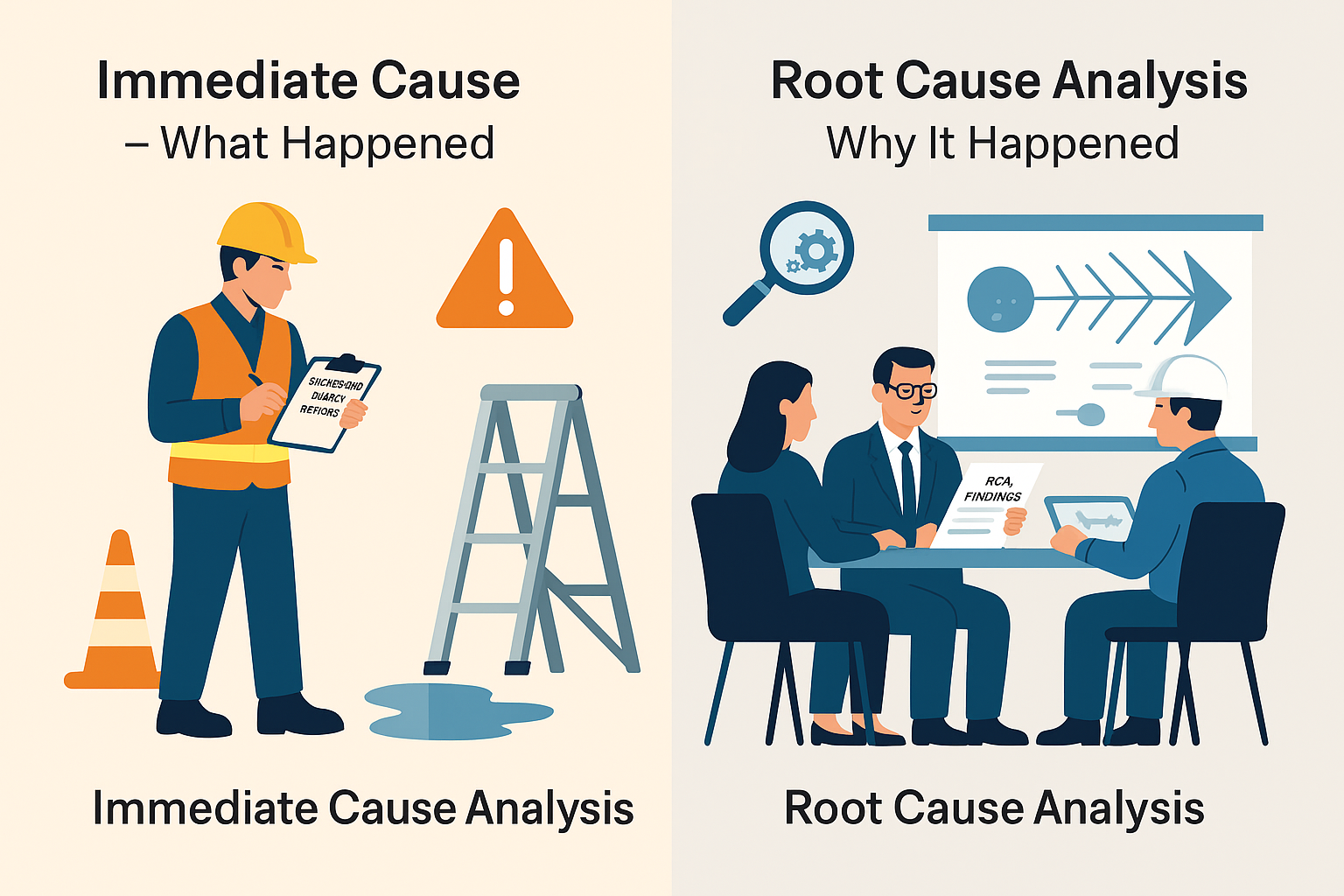

- Job Hazard Analysis (JHA): Systematic evaluation of rigging tasks to identify potential hazards.

- Safety Audits: Conducting regular audits to assess compliance with safety protocols and identify areas for improvement.

Identifying Common Rigging Hazards

- Overloading: Exceeding weight limits or capacity of rigging equipment.

- Slip and Trip Hazards: Risks associated with uneven or slippery surfaces in the rigging area.

Chapter 6: Safety Training and Certification

Importance of Rigging Training

- Skills Development: Providing rigging personnel with the necessary skills and knowledge to perform tasks safely.

- Compliance Requirements: Meeting training requirements mandated by regulatory agencies and industry standards.

Certification Requirements

- Rigging Certification Programs: Training programs that lead to certification for rigging personnel.

- Renewal and Recertification: Requirements for maintaining rigging certifications through periodic renewal and recertification.

Chapter 7: Emergency Procedures and Response

Emergency Preparedness

- Emergency Action Plans: Developing comprehensive plans for responding to rigging accidents and emergencies.

- First Aid Training: Providing rigging personnel with training in first aid and emergency response procedures.

Response Protocols for Rigging Accidents

- Immediate Actions: Steps to take in the event of a rigging accident, including stopping work and initiating emergency response procedures.

- Communication: Notifying appropriate personnel and emergency services promptly in case of an accident.

Chapter 8: Rigging Safety Quiz

Purpose of the Quiz

The quiz serves as an interactive tool to assess understanding and reinforce key rigging safety concepts covered in the ebook.

Sample Questions and Answers

- Question: What is the primary purpose of conducting a job hazard analysis (JHA) in rigging operations?

- Answer: The primary purpose of JHA is to systematically evaluate rigging tasks to identify potential hazards and implement preventive measures.

- Question: Why is proper equipment inspection essential in rigging safety?

- Answer: Proper equipment inspection ensures that rigging equipment is in good condition, reducing the risk of equipment failure and accidents.

Tips for Success

- Study Regularly: Review the ebook content thoroughly to prepare for the quiz effectively.

- Practice Quizzes: Take practice quizzes to assess understanding and identify areas for improvement before attempting the actual quiz.

Conclusion

Rigging safety is vital for protecting the well-being of workers and ensuring the success of lifting operations. Download our Rigging Safety Quiz Ebook today to enhance your rigging safety knowledge and contribute to creating safer work environments.

Construction Safety Quiz Ebook: Free Download

Confined Space Safety Quiz Ebook: Free Download

Chemical Safety Quiz Ebook: Free Download

Welding Safety Ebook: Hazards and Control Measures – Free Download

Steel Erection Safety Ebook: Hazards and Control Measures – Free Download

FAQs

What are the main hazards in rigging operations?

The main hazards include fall hazards, struck-by hazards, overloading, and slip and trip hazards.

Who should read this Rigging Safety Quiz Ebook?

This ebook is essential for rigging personnel, safety officers, supervisors, and anyone involved in rigging operations who wants to enhance their safety knowledge and skills.

What are some key safety tips highlighted in the Ebook?

Key safety tips highlighted in the ebook include the importance of proper equipment inspection, adherence to weight limits, clear communication during lifting operations, and emergency preparedness.

Why is continuous training essential for rigging safety?

Continuous training is essential for rigging safety as it helps to keep workers updated on the latest safety protocols, equipment usage guidelines, and regulatory requirements. It reinforces safe work practices, enhances hazard awareness, and ensures that personnel are prepared to handle rigging tasks safely.

Thankyou so much sir

I am more happy doing this because I am getting knowledge rigging safety.