Material Handling Safety Toolbox Talk (TBT)

Introduction

Good morning, everyone. Today, we are going to discuss Material Handling Safety—an important topic that affects our daily tasks. Improper handling of materials can lead to injuries such as back strains, muscle sprains, fractures, or even more serious accidents. Our goal is to ensure that we handle materials safely and avoid injuries.

We will cover the following points:

- Common Hazards in Material Handling

- Proper Lifting Techniques

- Use of Mechanical Aids

- Housekeeping and Storage Practices

- Personal Protective Equipment (PPE)

- Safety Rules for Manual and Mechanical Handling

- Emergency Procedures in Case of an Accident

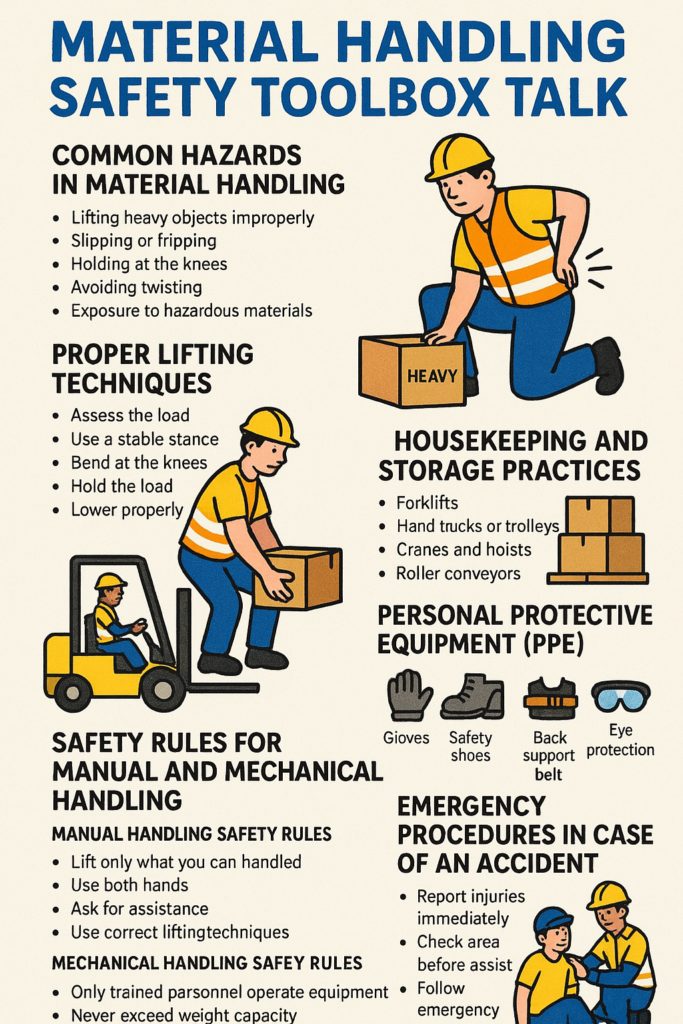

1. Common Hazards in Material Handling

When handling materials, we need to be aware of potential hazards that could cause injuries. These hazards include:

- Lifting heavy objects improperly, leading to back or muscle injuries.

- Slipping or tripping due to misplaced materials.

- Dropping materials on feet or hands.

- Getting caught in or between moving equipment.

- Exposure to hazardous materials, such as sharp edges or toxic substances.

2. Proper Lifting Techniques

To prevent back and muscle injuries, follow these correct lifting steps:

- Assess the load: Before lifting, check the weight and size of the object. If it’s too heavy, ask for help or use a mechanical aid.

- Use a stable stance: Stand with your feet shoulder-width apart for balance.

- Bend at the knees, not the waist: Keep your back straight and use your legs to lift.

- Hold the load close to your body: This helps maintain control and reduces strain on your muscles.

- Avoid twisting while lifting: Turn your whole body instead of twisting your back.

- Lower the load properly: Squat down while keeping your back straight when placing the object down.

3. Use of Mechanical Aids

Whenever possible, use mechanical aids such as:

- Forklifts for heavy lifting and transporting loads over long distances.

- Hand trucks or trolleys for moving medium-weight loads safely.

- Cranes and hoists for lifting extremely heavy materials.

- Roller conveyors to reduce manual handling.

Before using any equipment, ensure:

- It is in good condition and has been inspected.

- The operator is trained and authorized.

- Loads are secured properly to avoid shifting during movement.

4. Housekeeping and Storage Practices

Good housekeeping and proper storage reduce the risk of accidents. Follow these guidelines:

- Store materials in a stable manner to prevent falling.

- Keep aisles and walkways clear of obstructions.

- Stack materials properly—heavier items at the bottom and lighter ones on top.

- Use racks and shelves designed for the weight of the materials stored.

- Dispose of waste materials promptly to prevent trip hazards.

5. Personal Protective Equipment (PPE)

Depending on the type of materials being handled, the following PPE may be required:

- Gloves to protect hands from cuts, burns, or chemical exposure.

- Safety shoes with steel toes to prevent foot injuries from falling objects.

- Back support belts when handling heavy loads frequently.

- Eye protection when handling materials that could cause dust or debris to enter the eyes.

Always inspect your PPE before use and report any damaged equipment immediately.

6. Safety Rules for Manual and Mechanical Handling

Manual Handling Safety Rules:

✅ Lift only what you can handle safely.

✅ Use both hands when lifting an object.

✅ Ask for assistance if the load is too heavy.

✅ Use correct lifting techniques to avoid strain.

Mechanical Handling Safety Rules:

✅ Only trained personnel should operate material handling equipment.

✅ Never exceed the weight capacity of forklifts or cranes.

✅ Keep hands and feet clear of moving parts.

✅ Use signals and communication when moving large or hazardous loads.

7. Emergency Procedures in Case of an Accident

- Report injuries immediately: Even minor strains should be reported to prevent further complications.

- In case of a fall or dropped object, ensure the area is safe before assisting an injured coworker.

- If handling hazardous materials, follow emergency spill response procedures.

- Use first aid as needed until professional medical help arrives.

Example Scenario: Unsafe vs. Safe Material Handling

Unsafe Handling:

Ahmed is lifting a heavy box by bending over and using only his back. He twists while lifting and suddenly feels pain in his lower back. As a result, he drops the box, nearly injuring his coworker’s foot.

Safe Handling:

Ahmed first checks the weight of the box. Realizing it is too heavy, he calls his coworker for help. They both lift the box using their legs, keeping it close to their bodies. They safely transport and place the box without any injuries.

This example shows how proper lifting techniques and teamwork prevent injuries.

Conclusion and Worker Participation

Material handling safety is everyone’s responsibility. By following proper techniques, using PPE, and keeping work areas organized, we can prevent injuries and improve workplace safety.

Discussion Questions for Workers:

- Have you experienced or witnessed an incident related to improper material handling?

- What challenges do you face when lifting or moving heavy objects?

- Do you have any suggestions to improve material handling safety at our workplace?

Thank you for your attention. Stay safe and always follow proper material handling procedures!

Forklift Safety Toolbox Talk (TBT)

Crane Safety Toolbox Talk (TBT)

Painting Safety Toolbox Talk (TBT)

Plumbing and sanitary works job safety analysis

I want to be learning all safety rule thanks