Lockout and Tagout – LOTO Procedures Toolbox Talk (TBT)

Introduction

Good morning, everyone. Today’s Toolbox Talk is about Lockout and Tagout (LOTO) Procedures—one of the most important safety procedures in preventing serious injuries and fatalities caused by unexpected equipment start-ups or energy releases.

Many workplace accidents occur when machinery is accidentally energized while being serviced, maintained, or repaired. LOTO procedures help protect workers by isolating energy sources and ensuring that equipment cannot be turned on until work is safely completed.

During today’s discussion, we will cover:

- What is Lockout/Tagout (LOTO)?

- Why is LOTO important?

- Types of hazardous energy

- When should LOTO be used?

- Step-by-step LOTO procedure

- LOTO devices and equipment

- Common mistakes and violations

- Legal requirements and company policies

- Emergency situations and LOTO failure prevention

- Your role in ensuring a safe workplace

Let’s go through these topics one by one.

1. What is Lockout/Tagout (LOTO)?

LOTO is a safety procedure that ensures machines or equipment are completely shut off, de-energized, and prevented from being restarted while servicing or maintenance work is being performed.

✅ Lockout: Using a lock and key system to physically prevent machinery from being turned on.

✅ Tagout: Attaching warning tags to inform workers that equipment is locked out and must not be operated.

🚨 Only authorized personnel should perform LOTO procedures!

2. Why is LOTO Important?

Failure to follow LOTO procedures can result in:

❌ Serious injuries, amputations, or fatalities

❌ Electric shocks or arc flashes

❌ Moving machine parts causing crushing injuries

❌ Uncontrolled release of hazardous energy

❌ Legal penalties and fines for non-compliance

🚨 LOTO saves lives! Proper lockout/tagout procedures ensure that no one gets hurt due to unexpected machinery activation.

3. Types of Hazardous Energy

Machinery and equipment store different types of energy that must be controlled before maintenance work begins.

| Type of Energy | Examples |

|---|---|

| Electrical Energy | Live wires, stored capacitor energy, generators |

| Mechanical Energy | Moving gears, rotating shafts, springs |

| Hydraulic Energy | Pressurized oil in hydraulic systems |

| Pneumatic Energy | Compressed air in cylinders or tanks |

| Thermal Energy | Heated surfaces, steam, hot fluids |

| Chemical Energy | Flammable or reactive chemicals |

🚨 Always identify all sources of hazardous energy before performing maintenance!

4. When Should LOTO Be Used?

LOTO should be applied in situations where equipment or machinery needs to be serviced, repaired, or maintained.

🔹 Before cleaning or lubricating machinery

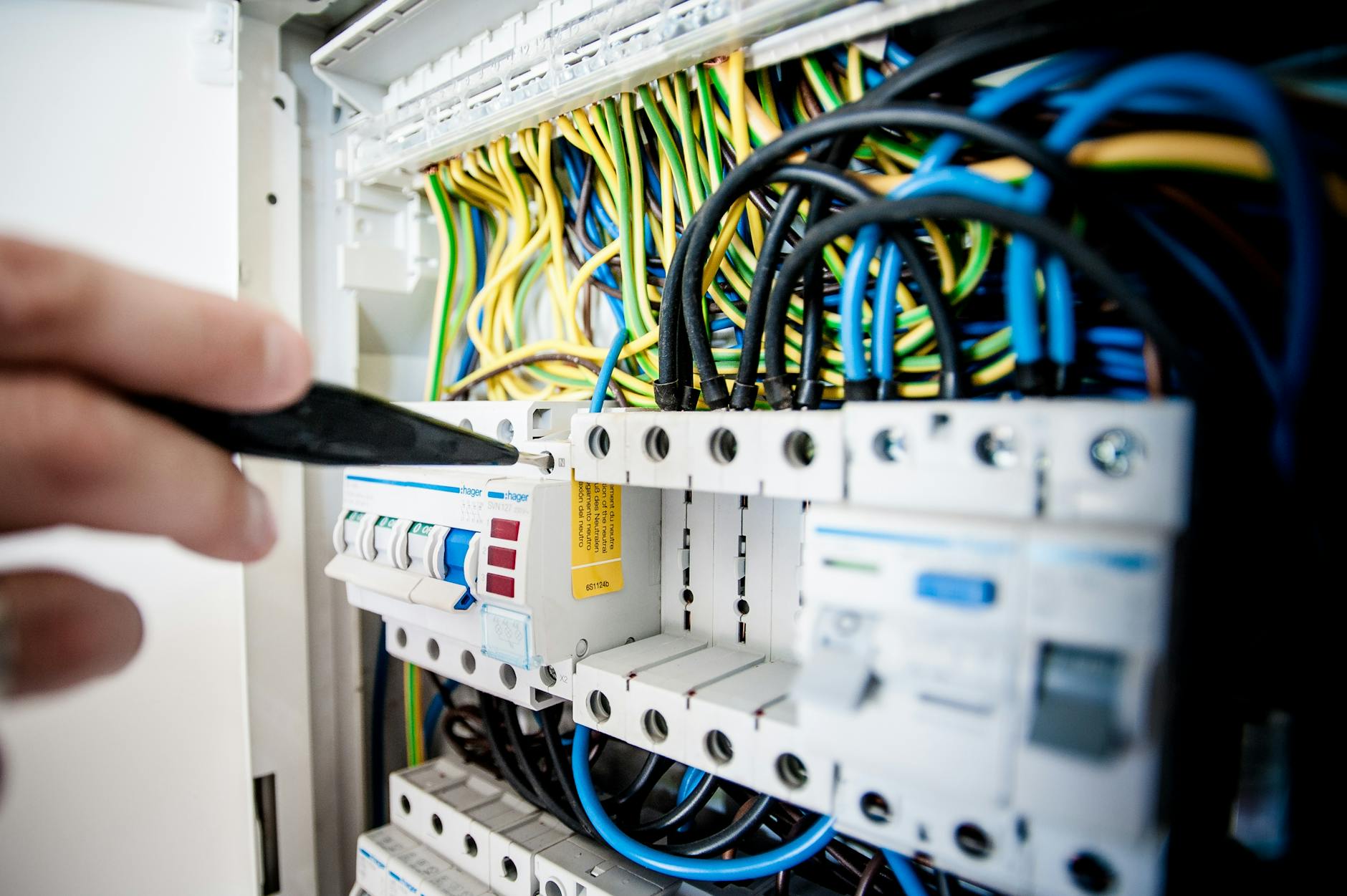

🔹 Before performing repairs on electrical equipment

🔹 When adjusting belts, blades, or moving parts

🔹 When replacing or changing machine parts

🔹 During inspections or testing procedures

🚨 Never assume a machine is safe—ALWAYS follow the LOTO procedure!

5. Step-by-Step LOTO Procedure

LOTO procedures must be followed exactly as per company policy to ensure safety.

Step 1: Prepare for Shutdown

✔ Identify the equipment that needs servicing.

✔ Notify all affected employees about the shutdown.

✔ Gather the necessary LOTO devices.

Step 2: Shut Down the Equipment

✔ Turn off the machine using the proper shutdown process.

✔ Make sure all moving parts have completely stopped.

Step 3: Isolate Energy Sources

✔ Disconnect or shut off ALL energy sources (electrical, mechanical, hydraulic, etc.).

Step 4: Lockout and Tagout

✔ Attach LOCKS to the energy control points.

✔ Place a TAG on the lock with a warning message.

✔ Each lock should have only ONE key (held by the authorized worker).

Step 5: Release Stored Energy

✔ Drain pressure from hydraulic and pneumatic systems.

✔ Discharge capacitors in electrical systems.

✔ Block or brace moving parts.

Step 6: Verify Lockout

✔ Double-check that all energy sources are completely isolated.

✔ Attempt to start the machine to ensure it cannot operate.

Step 7: Perform Maintenance Work

✔ Proceed with servicing only after verifying the equipment is safely locked out.

Step 8: Remove Locks and Restore Power

✔ Only the person who applied the lock should remove it.

✔ Inspect the equipment before restarting.

✔ Ensure all workers are clear of danger zones before re-energizing.

🚨 Skipping ANY step in this procedure can lead to serious injuries!

6. LOTO Devices and Equipment

LOTO equipment includes:

🔹 Padlocks – Secure energy control points

🔹 Lockout hasps – Allow multiple locks to be attached

🔹 Tagout labels – Provide warnings and instructions

🔹 Circuit breaker locks – Prevent accidental power restoration

🔹 Valve lockouts – Block gas or liquid flow

🔹 Cable lockouts – Secure multiple energy points

🚨 Only use company-approved LOTO devices for maximum safety!

7. Common Mistakes and Violations

❌ Not following proper LOTO procedures

❌ Using incorrect or unauthorized locks and tags

❌ Failing to verify isolation before starting work

❌ Removing someone else’s lock without authorization

❌ Restarting equipment without confirming safety clearance

🚨 Always double-check your LOTO process—mistakes can be fatal!

8. Legal Requirements and Company Policies

LOTO regulations are enforced by safety agencies like:

✔ OSHA (Occupational Safety and Health Administration)

✔ NFPA (National Fire Protection Association)

✔ ANSI (American National Standards Institute)

📌 Companies must have written LOTO policies, provide training, and enforce compliance.

🚨 Failure to follow LOTO laws can lead to fines and legal action.

9. Emergency Situations and LOTO Failure Prevention

🚨 In case of LOTO failure or violation:

✔ Stop work immediately

✔ Report the issue to a supervisor

✔ Secure the hazardous area

✔ Investigate and correct the problem before proceeding

🚨 Ignoring LOTO failures can lead to workplace fatalities!

10. Your Role in Ensuring a Safe Workplace

✅ Always follow the LOTO procedure—NO EXCEPTIONS!

✅ Use the correct locks, tags, and devices

✅ Never remove a lock or tag that isn’t yours

✅ Always verify that energy is fully isolated before working

✅ Report any LOTO violations or unsafe practices

🚨 Every worker is responsible for ensuring LOTO safety!

Conclusion

LOTO procedures are essential for preventing injuries and saving lives. Always follow the correct steps and never take shortcuts.

🔹 Does anyone have questions or experiences related to LOTO procedures?

Fall Protection Systems Toolbox Talk (TBT)

Ergonomics in the Workplace Toolbox Talk (TBT)

Reporting Incidents and Near Misses Toolbox Talk (TBT)

Sir PDF milega

Total topics pDf please sir