Gas Cutting Safety Ebook: Hazards and Control Measures – Free Download

Introduction

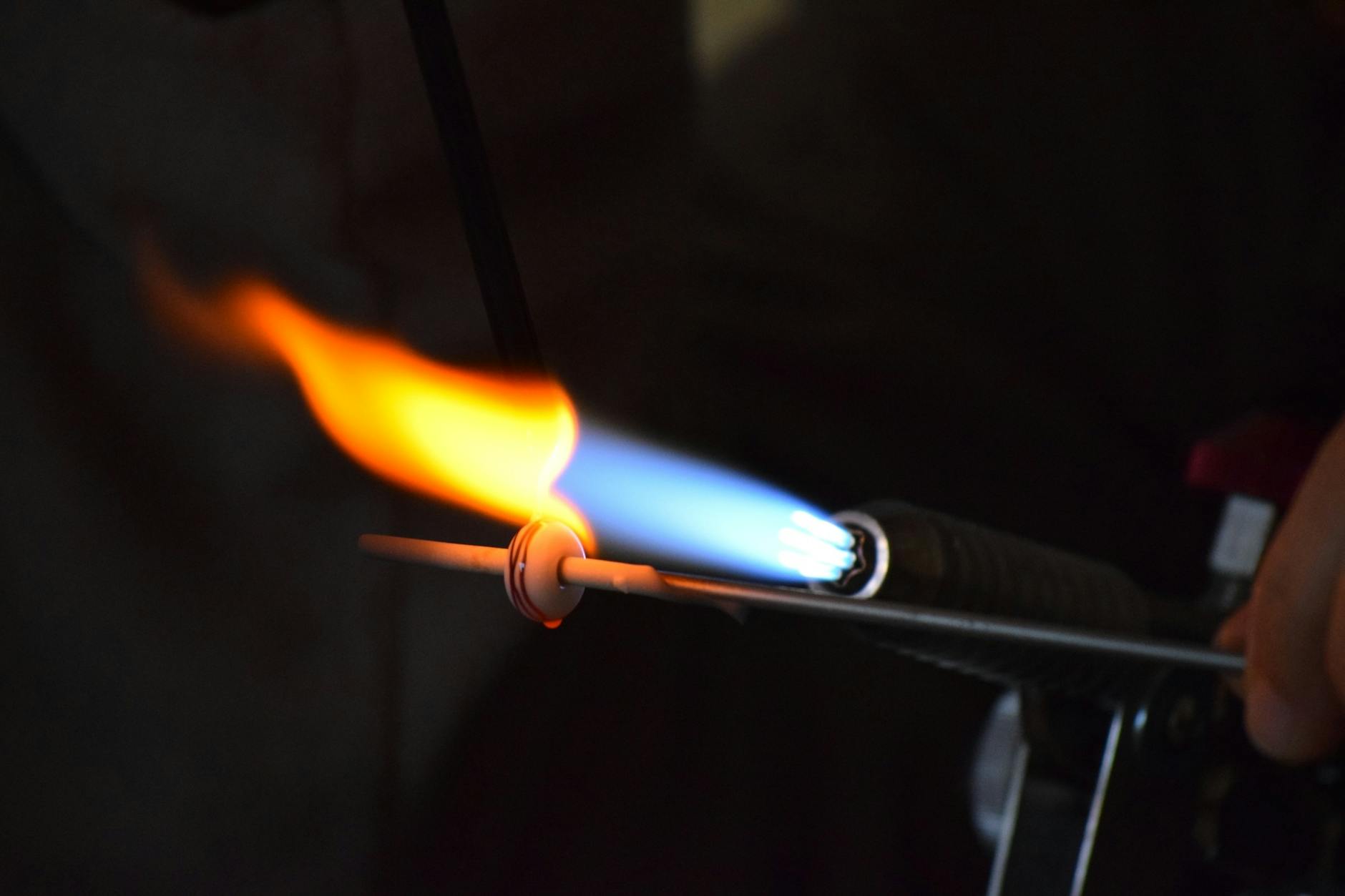

Gas cutting is a widely used method in metalworking and construction, but it comes with significant risks. Ensuring safety during gas cutting operations is crucial to prevent accidents and injuries. Our free Gas Cutting Safety Ebook, “Hazards and Control Measures,” provides comprehensive insights into maintaining a safe gas cutting environment. Let’s explore the key elements covered in this essential guide.

Chapter 1: Understanding Gas Cutting Hazards

Common Gas Cutting Hazards

Gas cutting operations come with several hazards. Recognizing these risks is the first step toward implementing effective safety measures.

Fire and Explosions

- Definition: Accidental ignition of gases can lead to fires and explosions.

- Consequences: Can cause serious injuries or fatalities and extensive property damage.

Toxic Fumes

- Risks: Inhalation of harmful gases produced during cutting.

- Prevention: Use of proper ventilation and respiratory protection.

Burns and Injuries

- Examples: Burns from hot metal or equipment and cuts from sharp edges.

- Prevention: Use of protective clothing and careful handling of materials.

Importance of Identifying Hazards

Identifying and understanding these hazards is crucial for developing and implementing appropriate control measures, thereby ensuring the safety of gas cutting operations.

Chapter 2: Safety Measures and Precautions

Personal Protective Equipment (PPE)

Using the right PPE is essential for anyone involved in gas cutting operations.

Types of PPE for Gas Cutting Operations

- Helmets: To protect against head injuries.

- Safety Glasses: To protect eyes from sparks and intense light.

- Gloves: To protect hands from burns and cuts.

- Flame-Resistant Clothing: To protect the body from heat and fire.

- Respirators: To protect against inhaling toxic fumes.

Gas Cutting Equipment Inspections and Maintenance

Regular inspection and maintenance of gas cutting equipment are vital for safety.

Routine Checks

- Visual Inspections: Regularly check for signs of wear, damage, or leaks.

- Functionality Tests: Ensure all parts of the equipment are functioning correctly.

Maintenance Protocols

- Scheduled Maintenance: Follow a routine maintenance schedule based on equipment usage and manufacturer recommendations.

- Record Keeping: Maintain detailed records of all inspections and maintenance activities.

Chapter 3: Safe Work Practices

Proper Setup and Operation of Gas Cutting Equipment

Using the correct setup and operating procedures is crucial to prevent accidents.

- Setup Procedures: Follow manufacturer guidelines for setting up equipment.

- Operation Techniques: Use best practices for operating gas cutting tools.

Safe Handling and Storage of Gas Cylinders

Proper handling and storage of gas cylinders are essential to prevent leaks and explosions.

- Handling Techniques: Always handle gas cylinders with care, avoiding rough treatment.

- Storage Guidelines: Store cylinders in a cool, dry place away from flammable materials.

Fire Safety Precautions

Fire safety is a primary concern in gas cutting operations.

- Fire Extinguishers: Ensure they are available and functional.

- No Smoking: Enforce no-smoking policies in and around the gas cutting area.

- Spark Control: Implement measures to control and contain sparks.

Chapter 4: Emergency Preparedness and Response

Importance of Emergency Plans

Having a comprehensive emergency plan can save lives and reduce injury severity.

- Evacuation Routes: Clearly mark exits and escape paths.

- Emergency Contacts: Ensure contact information for emergency services is readily available.

First Aid for Gas Cutting Injuries

Prompt first aid can prevent minor injuries from becoming major issues.

- First Aid Kits: Ensure kits are well-stocked and accessible.

- Training: Train workers in basic first aid and CPR.

Fire Safety Measures

Fire hazards are a serious concern in gas cutting operations.

- Fire Extinguishers: Ensure they are available and functional.

- No Smoking: Enforce no-smoking policies in hazardous areas.

- Flammable Materials: Store and handle flammable materials properly.

Chapter 5: Health and Ergonomics in Gas Cutting Operations

Preventing Musculoskeletal Disorders

Prolonged periods of gas cutting operations can lead to musculoskeletal disorders. Prevent these by:

- Stretching Exercises: Incorporate regular stretching routines.

- Proper Seating: Use ergonomically designed seats to reduce strain.

Ergonomic Tools and Techniques

Ergonomic considerations can reduce the risk of injury and enhance comfort:

- Tool Design: Use tools designed to minimize strain.

- Work Techniques: Implement techniques that reduce physical stress on the body.

Chapter 6: Training and Education

Importance of Continuous Training

Ongoing training ensures that workers stay informed about the latest safety practices and regulations.

Certification Programs for Gas Cutting Workers

Enroll in certification programs that cover:

- Hazard Recognition: Teach workers to identify and mitigate risks.

- Equipment Use: Train workers on the safe operation of gas cutting tools.

- Emergency Procedures: Prepare workers to handle emergencies.

Chapter 7: Legal Regulations and Standards

OSHA Standards for Gas Cutting Safety

Compliance with OSHA standards is essential for maintaining a safe work environment.

Understanding Local Safety Regulations

Different regions have specific safety regulations. Stay informed about:

- Building Codes: Adhere to local construction codes.

- Workplace Safety Laws: Follow local laws to avoid penalties.

Conclusion

Safety in gas cutting operations is not optional—it’s essential. By following the guidelines and measures outlined in our free Gas Cutting Safety Ebook, you can create a safer working environment for yourself and your team. Don’t wait until an accident happens; download the ebook today and stay ahead in safety.

FAQs

What is the main focus of the Gas Cutting Safety Ebook?

The ebook focuses on identifying common hazards in gas cutting operations and providing effective control measures to ensure a safe working environment.

How can I access the free Gas Cutting Safety Ebook?

You can download the ebook for free from our website. Just follow the link provided and fill in your details to get instant access.

Who should read this Gas Cutting Safety Ebook?

This ebook is ideal for construction workers, safety managers, project managers, and anyone involved in gas cutting operations.

What are some key safety tips mentioned in the Ebook?

Key tips include the use of PPE, proper handling of gas cutting equipment, maintaining a clean work environment, and having an emergency response plan.

Why is continuous training important in gas cutting safety?

Continuous training ensures that workers stay updated with the latest safety practices and regulations, reducing the risk of accidents and injuries.