Formwork Safety Interview: 50 Questions and Sample Answers

1. What is formwork in construction?

Answer: Formwork is a temporary or permanent mold used to support concrete while it sets and gains strength.

2. Why is formwork safety important?

Answer: Ensuring formwork safety prevents collapses, falls, and worker injuries, and helps maintain structural integrity.

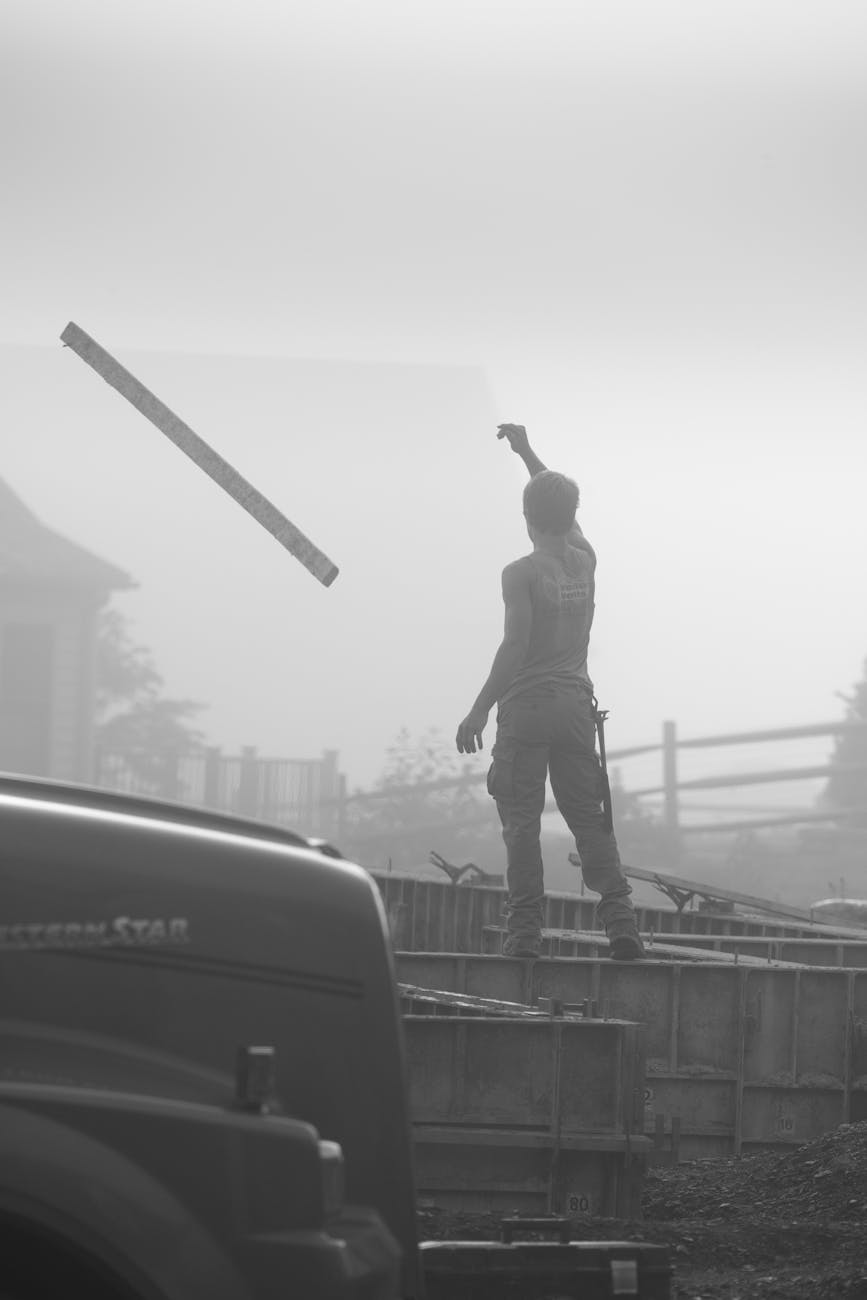

3. What are the main hazards associated with formwork?

Answer:

- Collapse of formwork due to weak support

- Falling from heights while assembling

- Struck-by hazards from materials falling

- Exposure to sharp edges and heavy loads

4. What are the different types of formwork used in construction?

Answer:

- Timber formwork

- Steel formwork

- Aluminum formwork

- Plastic formwork

- Fabric formwork

5. What is the role of a Safety Officer in formwork operations?

Answer: A Safety Officer ensures that formwork is properly installed, workers use PPE, and all safety procedures are followed.

6. What PPE is required for working with formwork?

Answer:

- Safety helmet

- Gloves

- Steel-toe boots

- Safety harness (for height work)

- Eye protection (goggles)

7. What is the safe height limit for formwork installation without scaffolding?

Answer: Typically, any work above 2 meters (6.5 feet) requires scaffolding or fall protection measures.

8. What are the basic steps in formwork installation?

Answer:

- Plan the design and layout.

- Prepare the ground and materials.

- Assemble and secure the framework.

- Inspect the formwork before pouring concrete.

- Monitor the structure during and after concrete placement.

9. How can we prevent formwork collapse?

Answer:

- Use proper bracing and supports.

- Ensure formwork components are strong enough.

- Avoid premature removal of supports.

- Conduct regular inspections before and during concrete pouring.

10. What is the minimum curing time before removing formwork?

Answer: It depends on concrete strength, but typically:

- Walls and columns: 24-48 hours

- Slabs (with props left in place): 3-7 days

- Beams and arches: 7-21 days

11. What safety precautions should be taken before pouring concrete into formwork?

Answer:

- Inspect formwork for stability and alignment.

- Check that reinforcement bars are correctly placed.

- Ensure proper access and escape routes.

- Remove unnecessary workers from the area.

12. What is the purpose of formwork bracing?

Answer: Bracing provides stability and prevents deformation or collapse of the formwork during concrete placement.

13. How do you inspect formwork before use?

Answer:

- Check for damaged or weak materials.

- Ensure correct alignment and secure connections.

- Verify that bracing and supports are in place.

14. What should be done if formwork starts to fail during concrete pouring?

Answer:

- Stop concrete pouring immediately.

- Evacuate workers from the danger zone.

- Reinforce weak sections and inspect for further risks.

15. Why should formwork be removed gradually?

Answer: Sudden removal can cause concrete cracking or collapse due to incomplete curing.

16. What are the risks of using defective formwork materials?

Answer:

- Formwork collapse

- Concrete leakage and instability

- Increased worker injury risks

17. How should timber formwork be stored?

Answer: Keep it dry, stacked properly, and protected from weather to prevent warping or decay.

18. What is shoring in formwork?

Answer: Shoring provides temporary support to keep structures stable before they become self-supporting.

19. How do you ensure proper ventilation while working with formwork in enclosed spaces?

Answer: Use exhaust fans, natural ventilation, or respirators to prevent exposure to harmful fumes.

20. What is the role of tie rods in formwork?

Answer: Tie rods hold the formwork panels together and prevent them from separating under concrete pressure.

21. Why should workers avoid standing on formwork before it is fully secured?

Answer: It may collapse or shift, leading to falls or injuries.

22. How can electrical hazards be avoided during formwork construction?

Answer:

- Use insulated tools.

- Keep formwork away from power lines.

- Inspect electrical cables and connections.

23. How does temperature affect formwork safety?

Answer:

- Cold weather can cause concrete to set slowly, requiring longer curing times.

- Hot weather can cause rapid drying, increasing the risk of cracks.

24. What safety measures should be taken when removing formwork?

Answer:

- Remove in small sections.

- Use proper tools instead of force.

- Ensure workers are not standing under the area being dismantled.

25. How should workers lift and handle heavy formwork panels safely?

Answer:

- Use mechanical lifting equipment.

- Lift with proper body posture.

- Work in teams to distribute the load.

26. What is falsework in formwork construction?

Answer: Falsework is temporary support for formwork, keeping it stable until the concrete is strong enough.

27. Why should rebar and sharp edges in formwork be covered?

Answer: To prevent worker injuries such as cuts and punctures.

28. How do weather conditions affect formwork stability?

Answer:

- Rain and wind can weaken supports.

- Extreme heat can cause wood formwork to expand.

29. Why is proper drainage necessary around formwork structures?

Answer: To prevent water accumulation, which can weaken the soil and supports.

30. How can noise hazards be controlled during formwork construction?

Answer:

- Use noise-reducing tools.

- Provide hearing protection for workers.

31. What are the risks of using improperly mixed concrete in formwork?

Answer:

- Weak structural integrity

- Formwork failure

- Cracks and defects in the final structure

32. What is the correct way to secure formwork panels?

Answer:

- Use strong fasteners and clamps

- Ensure proper alignment and leveling

- Double-check for loose connections before pouring concrete

33. What should you do if a formwork structure appears unstable?

Answer:

- Stop work immediately

- Reinforce supports and check for defects

- Report to the site supervisor for corrective action

34. How can scaffolding improve formwork safety?

Answer: Scaffolding provides safe access for workers, reducing fall hazards and improving stability.

35. Why is it important to use engineered formwork designs?

Answer:

- Ensures load-bearing capacity is met

- Reduces risk of failure or collapse

- Increases efficiency and worker safety

36. What is the purpose of releasing agents in formwork?

Answer: Releasing agents prevent concrete from sticking to formwork, making removal easier and reducing damage.

37. How can we prevent worker fatigue during formwork operations?

Answer:

- Schedule rotating shifts

- Provide breaks and hydration

- Use ergonomic lifting techniques

38. Why is edge protection required in elevated formwork?

Answer: To prevent falls and ensure worker safety during installation and dismantling.

39. What is the risk of premature removal of formwork?

Answer:

- Structural failure due to weak concrete

- Cracks and deformities in the structure

- Injuries from collapsing materials

40. What should be done in case of an accident involving formwork?

Answer:

- Stop work immediately

- Provide first aid and call emergency services

- Investigate and implement corrective measures

41. How do you ensure formwork stability on sloped or uneven ground?

Answer:

- Level the ground before installation

- Use adjustable props and extra bracing

- Conduct soil stability tests

42. What is the purpose of formwork ties?

Answer: They hold formwork panels together and resist concrete pressure during pouring.

43. How do you prevent trapped air bubbles in concrete poured into formwork?

Answer: Use vibrators to settle the concrete and eliminate air pockets.

44. What should be considered when designing tall formwork structures?

Answer:

- Wind loads and lateral stability

- Strong bracing and tie systems

- Safe access for workers

45. What are the best practices for dismantling formwork?

Answer:

- Remove sequentially from top to bottom

- Use proper tools instead of force

- Ensure no workers are below the removal area

46. How do weather conditions impact formwork safety?

Answer:

- Rain weakens timber and soil stability

- High temperatures cause wood expansion

- Strong winds make tall formwork unstable

47. What are the best safety measures when working at heights on formwork?

Answer:

- Use fall protection equipment (harness, guardrails)

- Secure ladders and platforms

- Train workers on safe height work procedures

48. How can material quality affect formwork safety?

Answer:

- Weak materials can cause collapse

- Poor-quality fasteners may fail under pressure

- Warped wood or rusted metal reduces stability

49. What are the legal requirements for formwork safety?

Answer:

- Follow OSHA and local construction safety standards

- Conduct regular inspections and certifications

- Ensure competent personnel handle formwork operations

50. How do you maintain a safe work environment in formwork operations?

Answer:

- Conduct daily safety briefings

- Implement strict PPE requirements

- Enforce safe work procedures and inspections

Painting Safety Interview: 50 Questions and Sample Answers

Environment Safety Interview: 50 Questions and Sample Answers

Offshore Safety Interview: 50 Questions and Sample Answers

Mobile Crane Safety Interview: 50 Questions and Sample Answers

Boom Truck Safety Interview: 50 Questions and Sample Answers