Fall Protection Anchor Point Requirements: Ensuring Safety at Heights

Fall protection is a critical aspect of workplace safety, especially in industries where working at heights is commonplace. Central to this safety mechanism are anchor points, which serve as the foundation for securing fall arrest systems. Understanding the requirements and standards for these anchor points is paramount to ensuring the safety and well-being of workers.

Introduction to Fall Protection Anchor Points

Importance of Anchor Points in Fall Protection

When working at heights, the risk of falls is a significant concern. Anchor points act as the pivotal connection between a worker’s harness and the fall arrest system, offering a secure point of attachment. They are crucial in preventing accidents and minimizing the potential impact of a fall.

Overview of Regulations and Standards

Regulatory bodies like the Occupational Safety and Health Administration (OSHA) have established stringent guidelines concerning fall protection anchor points. These regulations mandate specific requirements to ensure the reliability and safety of these anchor systems.

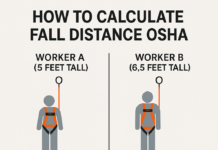

Understanding Fall Protection Anchor Point Requirements

Types of Anchor Points

There are various types of anchor points, including fixed, temporary, and certified anchor points. Each type caters to different work environments and applications, necessitating an understanding of their distinct characteristics and purposes.

Load Requirements and Testing Standards

Anchor points must adhere to specific load requirements and undergo rigorous testing to guarantee their strength and reliability. Understanding these standards is crucial in selecting the right anchor point for a particular work scenario.

OSHA Regulations for Anchor Points

OSHA Guidelines and Compliance

OSHA enforces comprehensive guidelines for anchor points, emphasizing their proper usage and maintenance. Compliance with these regulations is essential to avoid penalties and, more importantly, to safeguard workers’ lives.

Requirements for Different Industries

Different industries may have specific anchor point requirements based on the nature of work and potential fall hazards. Understanding these industry-specific regulations is vital for ensuring compliance.

Fall protection anchor points are crucial for ensuring the safety of individuals working at heights. Here are some general requirements for fall protection anchor points:- Strength: Anchor points must be able to support the intended load. They should be designed and installed to withstand the force generated during a fall.

- Certification: Anchor points should comply with relevant safety standards and certifications. For example, in the US, they might need to meet OSHA (Occupational Safety and Health Administration) regulations.

- Location: Anchor points should be strategically placed to provide sufficient coverage for workers in different areas where fall risks exist.

- Accessibility: They need to be easily accessible and not obstructed to allow for straightforward attachment of fall protection equipment.

- Attachment: The anchor point should allow for secure attachment of lanyards, lifelines, or other fall arrest systems.

- Regular Inspection: Routine inspections and maintenance are crucial to ensure the integrity of the anchor points. They should be checked for wear, corrosion, or any damage that might compromise their strength.

- Proper Installation: Correct installation by trained personnel following manufacturer guidelines is essential to ensure the reliability and safety of anchor points.

Remember, specific industries or regions might have additional requirements or standards for fall protection systems and anchor points. Always consult the relevant safety regulations and guidelines to ensure compliance and the safety of workers at heights.Selection and Installation of Anchor Points

Assessing Site-Specific Needs

Selecting the appropriate anchor points involves assessing the specific needs of a worksite, considering factors such as structure, height, and workload. This evaluation ensures the suitability and effectiveness of the anchor points.

Proper Installation Techniques

Correct installation is critical to the functionality of anchor points. Following manufacturer instructions and industry best practices is imperative to ensure their reliability during use.

Training and Maintenance

Training Requirements for Workers

Providing adequate training to workers on the proper use of anchor points and fall protection systems is essential. Workers must understand how to inspect, use, and maintain these systems effectively.

Regular Inspection and Maintenance Protocols

Regular inspections and maintenance routines are vital for ensuring the continued safety and functionality of anchor points. Adhering to maintenance schedules is crucial to prevent potential failures.

Innovations in Anchor Point Technology

Emerging Technologies in Fall Protection

Advancements in technology continue to revolutionize fall protection. Innovations such as smart anchor points and improved materials contribute to enhancing safety measures.

Advancements Improving Safety and Efficiency

These technological advancements not only improve safety but also enhance the efficiency of fall protection systems, making them more user-friendly and reliable.

Common Misconceptions about Anchor Point Requirements

Debunking Myths and Misconceptions

There are prevalent misconceptions about anchor points and their requirements. Addressing these misconceptions is crucial in ensuring accurate understanding and implementation.

Addressing Common Doubts

Common doubts regarding the effectiveness or necessity of anchor points need clarification. Providing comprehensive information helps in dispelling doubts and reinforcing the importance of these safety measures.

Case Studies and Examples

Real-Life Scenarios Highlighting Importance

Examining real-life scenarios where proper implementation of anchor points has prevented accidents or mitigated risks reinforces their significance in ensuring workplace safety.

Successful Implementation Stories

Case studies showcasing successful implementation and adherence to anchor point requirements serve as examples for other industries, emphasizing the positive impact on safety.

Evolving Standards and Future Outlook

Changes in Regulations and Industry Trends

Regulations and industry standards surrounding anchor point requirements are dynamic. Understanding these changes is essential for adapting and maintaining compliance.

Predictions for Future Requirements and Advancements

Predicting future trends and advancements in anchor point technology aids in preparing for upcoming changes, ensuring continuous improvement in fall protection measures.

Conclusion

In conclusion, adhering to fall protection anchor point requirements is crucial for ensuring the safety of workers at elevated work sites. Understanding the diverse types, regulations, installation procedures, and maintenance protocols is essential in mitigating fall risks and preventing accidents.

Full Body Harness 100% Tie Off

Fall Protection Plan Requirements

FAQs

- Are anchor points mandatory for all work at heights? Anchor points are essential for fall protection when working at heights. They are mandated in many industries and scenarios where there is a risk of falls.

- How often should anchor points be inspected? Regular inspections are crucial to ensure the safety and functionality of anchor points. Typically, they should be inspected at least annually or as per manufacturer recommendations.

- Can anchor points be reused in different work environments? Anchor points should be evaluated for compatibility with different work environments. Reusing them might be feasible, but it’s essential to ensure they meet the specific requirements of each environment.

- What are the consequences of not complying with anchor point requirements? Non-compliance with anchor point requirements can result in severe consequences, including workplace accidents, injuries, fines, and legal liabilities.

- Are there any specific requirements for anchor points in construction sites? Yes, construction sites often have specific regulations regarding anchor points due to the nature of work involved. Compliance with these requirements is critical for ensuring safety and adherence to standards.