Ergonomics in the Workplace Toolbox Talk (TBT)

Introduction

Good morning, everyone. Before we begin our tasks today, let’s talk about an important topic: Ergonomics in the Workplace.

Many of us spend long hours lifting, bending, pushing, pulling, sitting, or standing. Poor posture, repetitive movements, or improper lifting techniques can lead to injuries such as muscle strain, back pain, and joint problems.

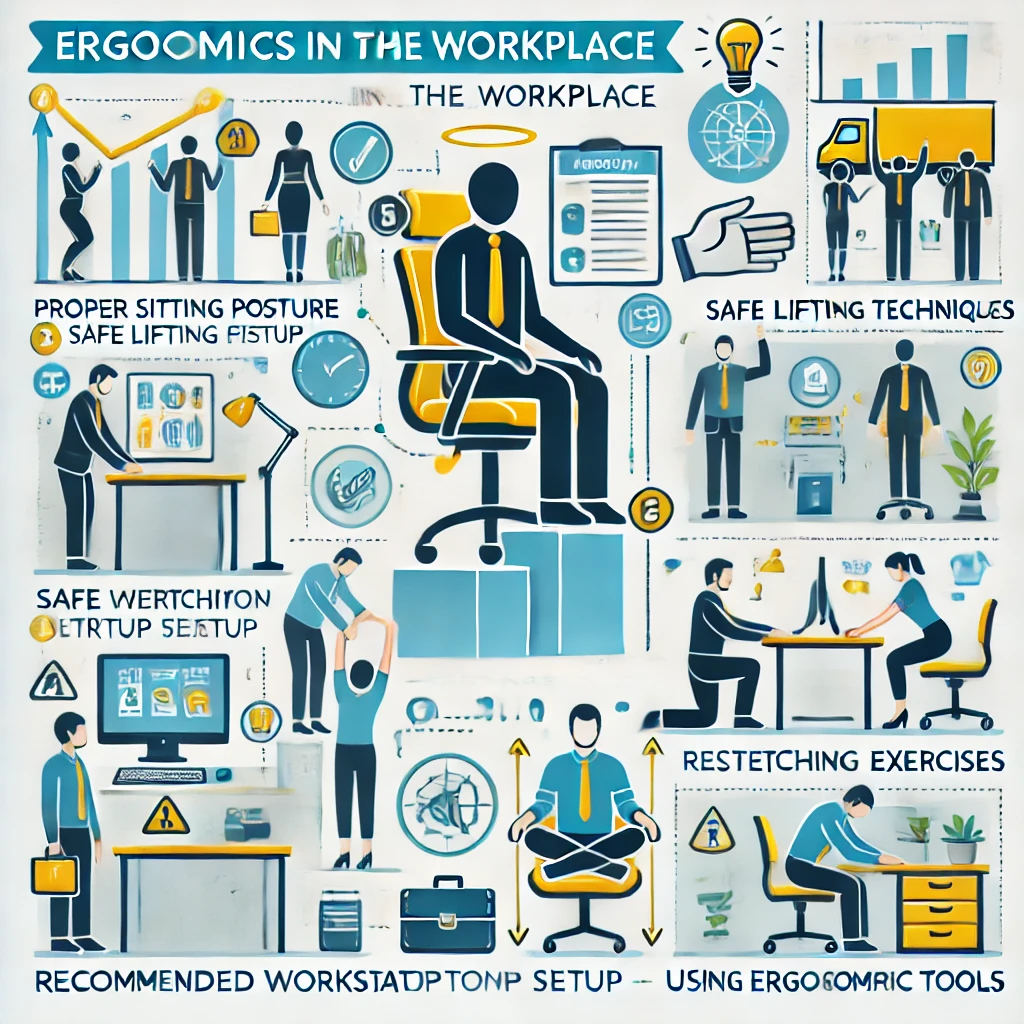

Today’s discussion will cover:

- What is ergonomics?

- Common ergonomic hazards in the workplace.

- How poor ergonomics leads to injuries.

- Best practices to prevent ergonomic injuries.

- Safe lifting techniques.

- The importance of stretching and body movement.

- Examples of ergonomic hazards and solutions.

- Your role in maintaining good workplace ergonomics.

By the end of this talk, you will have the knowledge to reduce workplace injuries, improve comfort, and enhance productivity.

1. What is Ergonomics?

Ergonomics is the science of designing the workplace to fit the worker, rather than forcing the worker to fit the workplace. It focuses on:

✅ Reducing strain on the body.

✅ Improving comfort and efficiency.

✅ Preventing musculoskeletal disorders (MSDs).

✅ Enhancing work performance and safety.

Fact: According to studies, one-third of all workplace injuries are related to poor ergonomics. This includes back injuries, wrist strain, and joint pain.

2. Common Ergonomic Hazards in the Workplace

🚨 Repetitive Movements: Performing the same action repeatedly (e.g., assembly line work, typing, lifting boxes).

🚨 Poor Posture: Slouching, twisting, or bending awkwardly while working.

🚨 Heavy Lifting: Carrying loads without proper lifting techniques.

🚨 Vibration & Tool Use: Using vibrating tools for long periods (e.g., jackhammers, drills).

🚨 Standing or Sitting for Long Periods: Lack of movement leads to strain on legs and back.

3. How Poor Ergonomics Leads to Injuries

Ignoring ergonomics can cause:

❌ Muscle fatigue and soreness.

❌ Back, neck, and shoulder pain.

❌ Carpal tunnel syndrome (wrist and hand strain).

❌ Knee and joint problems.

❌ Long-term disabilities if left untreated.

Example: If you lift heavy objects incorrectly, you could develop lower back pain over time. If you use vibrating tools for long hours without breaks, you could suffer from hand-arm vibration syndrome (HAVS).

4. Best Practices to Prevent Ergonomic Injuries

🔹 Use Proper Body Mechanics: Keep your back straight and avoid twisting motions.

🔹 Adjust Your Workstation: Ensure your tools, desk, and chair are at a comfortable height.

🔹 Take Breaks: Short breaks reduce muscle fatigue and improve circulation.

🔹 Use Mechanical Aids: When lifting heavy objects, use dollies, forklifts, or cranes.

🔹 Maintain Neutral Posture: Keep your body in a natural, relaxed position.

🔹 Use Anti-Fatigue Mats: If you stand for long periods, use mats to reduce strain on your legs.

🔹 Stretch Regularly: Stretching helps prevent stiffness and injuries.

5. Safe Lifting Techniques

Lifting objects improperly is one of the most common causes of workplace injuries. Follow these steps:

✅ Assess the Load: Check if it’s too heavy before lifting. Ask for help if needed.

✅ Use a Wide Stance: Keep your feet shoulder-width apart for balance.

✅ Bend Your Knees: Squat instead of bending at the waist.

✅ Keep the Load Close: Hold the object close to your body.

✅ Lift With Your Legs: Your legs, not your back, should do the work.

✅ Avoid Twisting: Turn your whole body instead of twisting your spine.

✅ Put Down Slowly: Lower the object by bending your knees.

🚨 Never lift heavy objects above shoulder level! Use a ladder or mechanical aid instead.

6. The Importance of Stretching and Body Movement

📌 Stretching improves flexibility and reduces stiffness.

📌 It prevents muscle injuries caused by sudden movements.

📌 It increases blood flow and keeps you energized.

📌 Simple stretching before work can reduce the risk of sprains and strains by 50%!

Quick Stretching Exercises:

✅ Neck Stretch: Slowly tilt your head side to side.

✅ Shoulder Rolls: Rotate your shoulders forward and backward.

✅ Back Stretch: Stand up and gently stretch backward.

✅ Leg Stretch: Stretch your legs and hold for 10-15 seconds.

Tip: Make stretching part of your daily routine before starting work.

7. Examples of Ergonomic Hazards & Solutions

Example 1: Improper Chair Setup (Office Work)

❌ Problem: A worker uses a chair that is too low, causing them to hunch over their desk.

✅ Solution: Adjust the chair so the feet are flat on the floor and the back is supported. Use an ergonomic keyboard and mouse.

Example 2: Heavy Manual Lifting (Warehouse Work)

❌ Problem: A worker frequently lifts heavy boxes without bending their knees.

✅ Solution: Train workers on safe lifting techniques and provide lifting aids like forklifts or dollies.

Example 3: Long Standing (Construction Site)

❌ Problem: A worker stands on a hard surface for long hours without movement.

✅ Solution: Use anti-fatigue mats, provide seating for breaks, and encourage shifting weight periodically.

8. Your Role in Maintaining Good Workplace Ergonomics

👷 Be aware of your body posture and movements.

👷 Report any ergonomic hazards to your supervisor.

👷 Follow proper lifting techniques and use mechanical aids when needed.

👷 Take short breaks to rest and stretch.

👷 Use the correct tools for the job.

👷 Encourage coworkers to practice good ergonomics.

REMEMBER: Good ergonomics protects your health, reduces injuries, and increases efficiency. Your well-being is the most important part of the job!

Conclusion

Ergonomics is not just about comfort—it’s about preventing long-term injuries and improving workplace safety. By following proper ergonomic practices, you will reduce fatigue, prevent pain, and work more efficiently.

🚧 Let’s all commit to practicing good ergonomics and looking out for each other’s safety.

🔹 Does anyone have any questions or experiences related to ergonomics at work?

First Aid Basics Toolbox Talk (TBT)

Hand and Power Tool Safety Toolbox Talk (TBT)

Welding and Cutting Safety Toolbox Talk (TBT)

HIRA Toolbox Talk (TBT) – Hazard Identification and Risk Assessment

Very useful. I appreciate