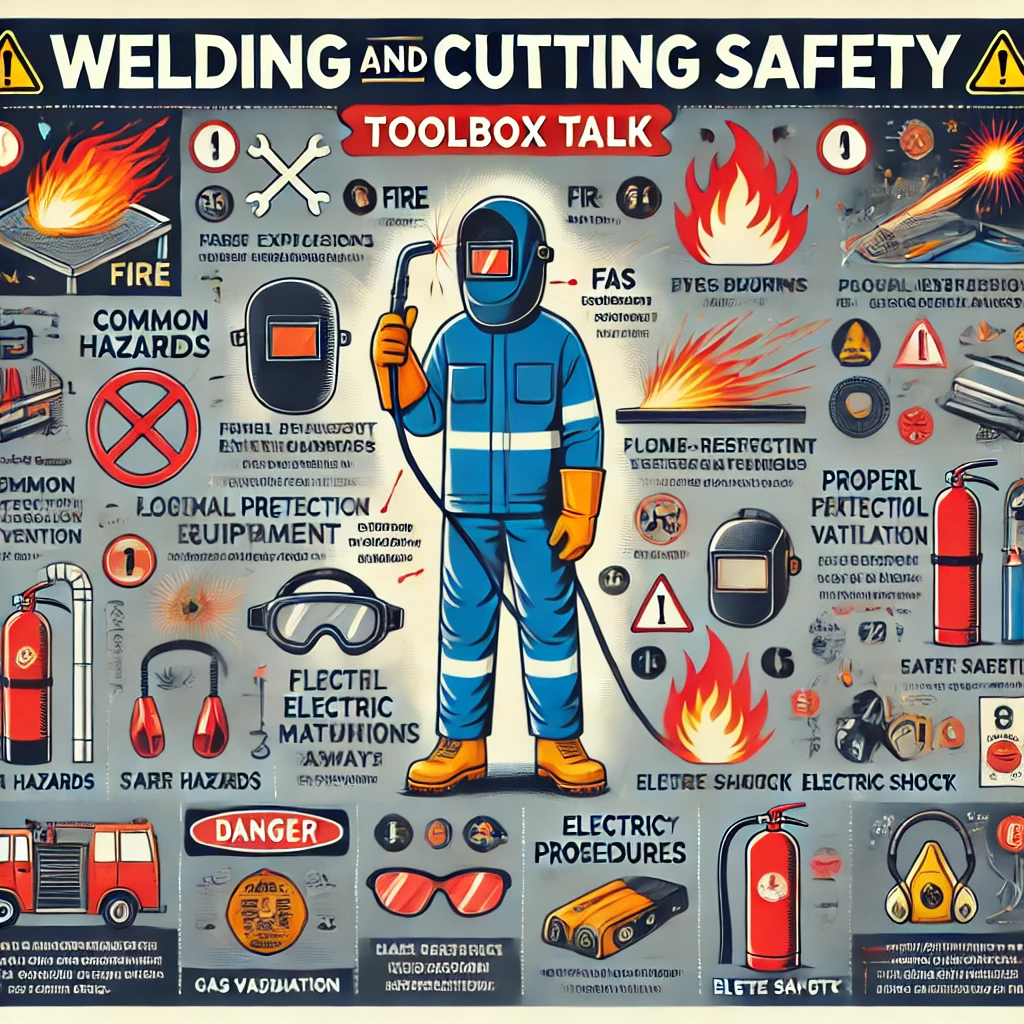

Welding and Cutting Safety Toolbox Talk (TBT)

Introduction

Good morning, team! Today, we will discuss an essential safety topic—Welding and Cutting Safety.

Welding and cutting operations involve high heat, open flames, and sparks, which can lead to serious injuries or accidents if proper precautions are not followed. By understanding the hazards and implementing safety measures, we can prevent burns, eye injuries, fires, and explosions.

🚧 Safety starts with knowledge and proper procedures! 🚧

Topics Covered:

- Common Hazards in Welding and Cutting

- Personal Protective Equipment (PPE) Requirements

- Fire and Explosion Prevention

- Proper Ventilation and Fume Control

- Safe Handling of Gas Cylinders

- Electrical Safety in Welding Operations

- Hot Work Permit and Safety Procedures

- Emergency Procedures and First Aid

- Conclusion and Worker Participation

1. Common Hazards in Welding and Cutting

Welding and cutting pose multiple hazards, including:

🔥 Fire and Explosions – Sparks can ignite flammable materials.

🔥 Burns – Contact with hot metal, slag, or flames can cause severe burns.

🔥 Eye Damage – Ultraviolet (UV) and infrared (IR) radiation can cause arc eye (welding flash).

🔥 Respiratory Hazards – Welding fumes contain toxic gases that can harm the lungs.

🔥 Electric Shock – Improper grounding or damaged cables can lead to electrocution.

🔥 Noise and Heat Stress – Prolonged exposure can cause hearing loss and fatigue.

🚧 Being aware of these hazards is the first step to preventing accidents! 🚧

2. Personal Protective Equipment (PPE) Requirements

Workers must wear the proper PPE to protect themselves:

✔ Welding Helmet with Proper Lens Shade – Protects eyes from UV/IR radiation and sparks.

✔ Safety Glasses with Side Shields – Worn under the welding helmet for extra eye protection.

✔ Flame-Resistant Gloves and Clothing – Protects from burns and hot metal splashes.

✔ Leather Apron and Sleeves – Shields against heat and sparks.

✔ Respirator or Welding Fume Mask – Prevents inhalation of toxic fumes.

✔ Ear Protection (Earplugs or Earmuffs) – Reduces noise exposure.

✔ Steel-Toe Boots with Metatarsal Guards – Protects feet from falling objects and sparks.

🚧 Always wear the appropriate PPE before starting any welding or cutting work! 🚧

3. Fire and Explosion Prevention

🔥 Fire is one of the biggest risks in welding and cutting operations. Follow these steps to prevent fires:

✔ Clear the work area of flammable materials.

✔ Use fire-resistant blankets or shields to contain sparks.

✔ Have a fire extinguisher nearby (Class ABC or CO₂ extinguisher).

✔ Ensure proper grounding of welding equipment.

✔ Assign a fire watch if working in a hazardous area.

🚧 A small spark can start a big fire—always stay alert! 🚧

4. Proper Ventilation and Fume Control

Welding and cutting create hazardous fumes that can cause lung diseases. Follow these guidelines:

✔ Work in well-ventilated areas.

✔ Use local exhaust ventilation systems or fans.

✔ Avoid welding in confined spaces without proper precautions.

✔ Wear an appropriate respirator if ventilation is inadequate.

🚧 Never ignore fumes—protect your lungs! 🚧

5. Safe Handling of Gas Cylinders

Oxygen and fuel gas cylinders must be handled with care to prevent leaks and explosions. Follow these rules:

✔ Store cylinders upright and secure them with chains.

✔ Keep oxygen and fuel gas cylinders separated (minimum 20 feet apart).

✔ Use regulators and check for leaks before use.

✔ Close the valves and release gas pressure when not in use.

✔ Never use oil or grease on oxygen regulators or fittings.

🚧 Gas cylinders can be dangerous if mishandled—treat them with caution! 🚧

6. Electrical Safety in Welding Operations

Welding equipment operates on high voltage and can cause electric shocks. Follow these safety tips:

✔ Inspect cables and connectors for damage before use.

✔ Ensure proper grounding of welding machines.

✔ Use dry gloves and stand on an insulated surface while welding.

✔ Never touch the electrode or welding wire with bare hands.

✔ Disconnect power before repairing or maintaining equipment.

🚧 Electricity is silent but deadly—always check your equipment! 🚧

7. Hot Work Permit and Safety Procedures

Before starting welding or cutting in restricted areas, a Hot Work Permit must be obtained. The permit ensures:

✔ Risk assessment has been conducted.

✔ Fire safety measures are in place.

✔ A fire watch is assigned if needed.

✔ Nearby workers are aware of the hazards.

🚧 No hot work should be done without proper authorization! 🚧

8. Emergency Procedures and First Aid

🚨 In case of an emergency, follow these steps:

🔥 Fire:

✔ Stop work immediately.

✔ Use the correct fire extinguisher.

✔ Call emergency services if the fire spreads.

⚡ Electric Shock:

✔ Turn off the power source.

✔ Do not touch the person until the power is off.

✔ Seek medical attention immediately.

👁️ Eye Injury (Welding Flash):

✔ Flush eyes with clean water for at least 15 minutes.

✔ Seek medical attention if symptoms persist.

🚧 Quick action can save lives—know your emergency plan! 🚧

9. Conclusion and Worker Participation

Welding and cutting are high-risk activities, but with proper precautions, we can prevent accidents.

Key Takeaways:

✔ Always wear the correct PPE.

✔ Prevent fires by keeping flammable materials away.

✔ Ensure proper ventilation and fume extraction.

✔ Handle gas cylinders safely and check for leaks.

✔ Follow electrical safety guidelines.

✔ Obtain a Hot Work Permit before starting work.

✔ Know emergency procedures and first aid steps.

Discussion Questions:

- Have you experienced a welding or cutting hazard before?

- What steps can we take to improve welding safety at our site?

- How can we encourage safe practices among all workers?

🚧 Let’s work together to ensure a safe work environment! 🚧

Thank you, and stay safe!

Vibration Safety Toolbox Talk (TBT)

Radiography Safety Toolbox Talk (TBT)

Hydrotest Safety Toolbox Talk (TBT)

Nice work sir