Hot Work Safety Toolbox Talk (TBT)

Introduction

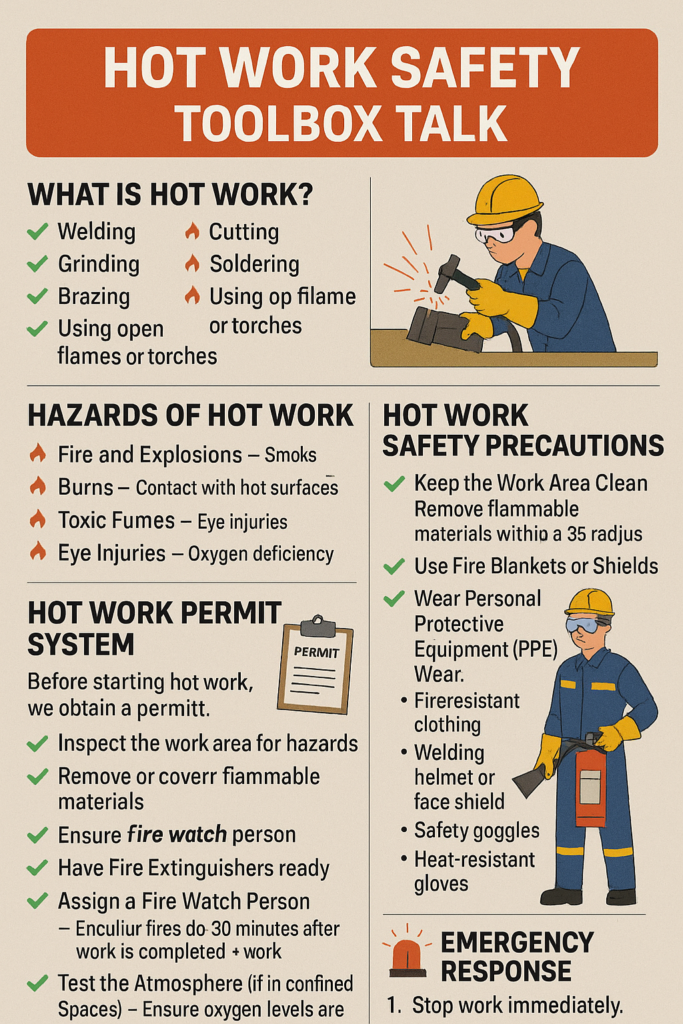

Good morning, everyone! Today, we will discuss Hot Work Safety. Hot work includes activities like welding, cutting, grinding, brazing, and any other operation that generates heat, sparks, or flames. These activities can lead to fires, burns, and explosions if not handled properly. It is our responsibility to follow safety precautions to prevent accidents.

1. What is Hot Work?

Hot work refers to tasks that involve:

✅ Welding

✅ Cutting

✅ Grinding

✅ Soldering

✅ Brazing

✅ Using open flames or torches

These activities create heat, sparks, or flames, which can ignite flammable materials nearby.

2. Hazards of Hot Work

🔥 Fire and Explosions – Sparks can ignite nearby flammable materials.

🔥 Burns – Contact with hot surfaces, flames, or molten metal can cause severe burns.

🔥 Toxic Fumes – Welding and cutting release hazardous fumes that can be harmful if inhaled.

🔥 Eye Injuries – Bright light, UV rays, and flying sparks can cause serious eye damage.

🔥 Oxygen Deficiency – Working in confined spaces can lead to low oxygen levels.

3. Hot Work Permit System

Before performing hot work, we must obtain a Hot Work Permit. This ensures that safety measures are in place. The permit process includes:

✅ Inspecting the work area for hazards

✅ Removing or covering flammable materials

✅ Ensuring fire extinguishers are available

✅ Assigning a fire watch person

The work cannot begin until all safety conditions are met.

4. Hot Work Safety Precautions

✔ Keep the Work Area Clean – Remove flammable materials within a 35-foot radius.

✔ Use Fire Blankets or Shields – Protect nearby surfaces from sparks.

✔ Use Personal Protective Equipment (PPE) – Wear:

- Fire-resistant clothing

- Welding helmet or face shield

- Safety goggles

- Heat-resistant gloves

✔ Ensure Proper Ventilation – Prevent the buildup of toxic fumes.

✔ Have Fire Extinguishers Ready – Keep suitable fire extinguishers nearby.

✔ Assign a Fire Watch Person – Someone must watch for fires during and 30 minutes after work is completed.

✔ Test the Atmosphere (If in Confined Spaces) – Ensure oxygen levels are safe.

5. Emergency Response

🚨 If a fire starts:

- Stop work immediately.

- Use a fire extinguisher (if safe).

- Call for help and evacuate if necessary.

- Report all incidents to the supervisor.

Example Scenario

Imagine a worker is cutting metal in a confined area. Sparks are flying, and nearby there are oily rags and a wooden crate. If a fire starts, what should be done?

Solution:

✅ Stop work immediately.

✅ Use a fire extinguisher if it’s safe.

✅ Evacuate and report the fire.

✅ Ensure all flammable materials are removed before starting the work.

Conclusion

Hot work is dangerous, but by following the Hot Work Permit System and safety precautions, we can prevent accidents. Always wear proper PPE, keep the area clean, and have fire extinguishers ready. Safety is a shared responsibility, so let’s work together to keep our workplace safe!

Electrical Safety Toolbox Talk (TBT)

Excavation Safety Toolbox Talk (TBT)

Work at Height Safety Toolbox Talk (TBT)