Chemical Process Safety: Ensuring Safety in Industrial Operations

Chemical process safety is a crucial aspect of industrial operations that aims to prevent accidents and hazards associated with the handling, storage, and manufacturing of chemicals. It encompasses various measures and protocols designed to protect workers, the environment, and surrounding communities from potential risks posed by chemical processes.

Introduction to Chemical Process Safety

Chemical process safety involves the identification, evaluation, and mitigation of hazards associated with chemical processes. It encompasses a range of activities, including risk assessment, safety management systems, and emergency response planning. The goal is to prevent accidents, injuries, and environmental damage resulting from chemical releases or incidents.

Importance of Chemical Process Safety

The importance of chemical process safety cannot be overstated. Accidents in chemical plants can have catastrophic consequences, including loss of life, environmental pollution, and property damage. By implementing robust safety measures, organizations can minimize the risks associated with chemical processes and ensure the well-being of workers and the surrounding community.

Common Hazards in Chemical Processes

Chemical processes pose various hazards, including:

Chemical Reactions

Uncontrolled chemical reactions can lead to runaway reactions, resulting in fires, explosions, and the release of toxic substances.

Fire and Explosion Hazards

Many chemicals are flammable or explosive under certain conditions, making fire and explosion hazards a significant concern in chemical processes.

Toxic Release

Chemical spills or leaks can result in the release of toxic substances into the environment, posing risks to human health and the ecosystem.

Regulatory Standards and Guidelines

To ensure chemical process safety, regulatory agencies such as OSHA (Occupational Safety and Health Administration) and the EPA (Environmental Protection Agency) have established standards and guidelines that govern the handling, storage, and use of hazardous chemicals.

OSHA Regulations

OSHA regulations require employers to implement safety measures, provide training to workers, and maintain records of chemical hazards and exposures in the workplace.

EPA Guidelines

The EPA provides guidelines for the safe management and disposal of hazardous chemicals to prevent environmental contamination and protect public health.

Elements of Process Safety Management (PSM)

Process Safety Management (PSM) is a comprehensive approach to managing the risks associated with chemical processes. It involves several key elements, including:

Hazard Identification

Identifying and assessing potential hazards associated with chemical processes, equipment, and operations.

Risk Assessment

Evaluating the likelihood and consequences of potential accidents or incidents and implementing measures to reduce risks.

Prevention and Mitigation

Implementing engineering controls, safety protocols, and emergency response plans to prevent accidents and minimize their impact.

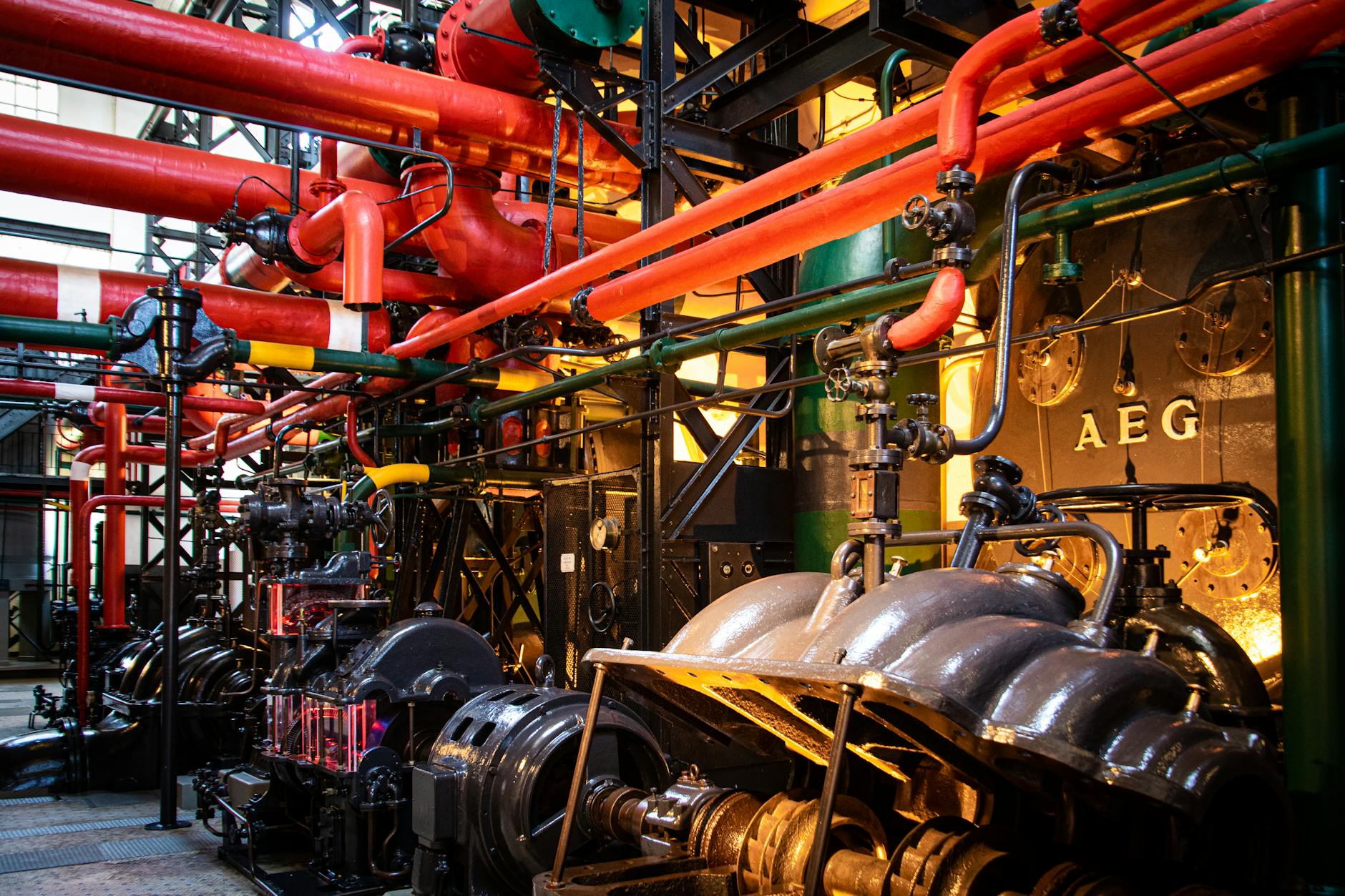

Safety Equipment and Engineering Controls

To enhance chemical process safety, various safety equipment and engineering controls are utilized, including:

Personal Protective Equipment (PPE)

Personal protective equipment such as gloves, goggles, and respirators is essential for protecting workers from chemical exposure and hazards.

Ventilation Systems

Proper ventilation systems help to control chemical vapors, dust, and fumes, reducing the risk of exposure and maintaining air quality in the workplace.

Emergency Shutdown Systems

Emergency shutdown systems automatically activate in response to abnormal conditions or hazards, helping to prevent accidents and mitigate their consequences.

Training and Education in Chemical Process Safety

Effective training and education programs are essential for ensuring that workers understand the hazards associated with chemical processes and know how to safely handle chemicals and equipment.

Chemical process safety is the field dedicated to preventing accidents, incidents, and emergencies in industries that handle hazardous chemicals. It encompasses a range of measures aimed at ensuring the safe design, operation, and maintenance of chemical processes and facilities. Key aspects of chemical process safety include:- Risk Assessment: Identifying and evaluating potential hazards associated with chemical processes, such as fire, explosion, toxic releases, and environmental contamination.

- Process Design: Designing chemical processes and equipment with safety considerations in mind, including the selection of appropriate materials, equipment layout, and process controls.

- Safety Instrumented Systems (SIS): Implementing safety systems, such as emergency shutdown systems and alarms, to mitigate the consequences of process deviations or failures.

- Operating Procedures: Developing and implementing procedures for the safe operation of chemical processes, including startup, shutdown, and emergency response protocols.

- Training and Education: Providing training to personnel involved in chemical processes to ensure they understand the risks and know how to operate equipment safely.

- Maintenance and Inspection: Regularly inspecting and maintaining equipment to prevent malfunctions and identifying potential safety hazards before they escalate.

- Management of Change: Implementing procedures to assess and manage the impact of changes to chemical processes, equipment, or operating conditions on safety.

- Emergency Response Planning: Developing plans and protocols to respond effectively to chemical spills, releases, fires, and other emergencies, including evacuation procedures and coordination with emergency responders.

- Regulatory Compliance: Ensuring compliance with relevant regulations and standards governing chemical process safety, such as those set forth by government agencies and industry organizations.

Overall, chemical process safety is essential for protecting workers, communities, and the environment from the potential risks associated with the handling and processing of hazardous chemicals.Conclusion

Chemical process safety is paramount in industrial operations to prevent accidents, protect workers, and safeguard the environment. By implementing robust safety measures, organizations can mitigate the risks associated with chemical processes and ensure the well-being of all stakeholders.

Chemical Hygiene in Laboratories: Promoting Safe Handling and Storage Practices

Chemical Handling: Storage and Personal Protective Equipment (PPE)

Chemical Exposure Monitoring: Air Sampling and Analysis

Chemical Spill Response: Containment and Cleanup

Hazardous Materials Transportation: Compliance and Emergency Response

FAQs on Chemical Process Safety

- What are the main goals of chemical process safety?

- The main goals of chemical process safety are to prevent accidents, protect workers, safeguard the environment, and ensure the safe handling, storage, and manufacturing of chemicals. By implementing robust safety measures, organizations aim to minimize the risks associated with chemical processes and ensure the well-being of all stakeholders.

- How can organizations improve their process safety management?

- Organizations can improve their process safety management by implementing comprehensive safety programs, conducting regular risk assessments, providing ongoing training to employees, maintaining proper equipment and infrastructure, fostering a culture of safety awareness, and continually evaluating and improving safety practices based on lessons learned from past incidents.

- What role do regulatory agencies play in chemical process safety?

- Regulatory agencies such as OSHA (Occupational Safety and Health Administration) and the EPA (Environmental Protection Agency) play a crucial role in chemical process safety by establishing standards, guidelines, and regulations that govern the handling, storage, and use of hazardous chemicals. These agencies conduct inspections, enforce compliance with safety regulations, and provide guidance and resources to help organizations maintain safe workplaces.

- What are some common challenges in implementing process safety measures?

- Some common challenges in implementing process safety measures include balancing safety requirements with operational efficiency, allocating sufficient resources for safety initiatives, ensuring compliance with evolving regulatory standards, addressing cultural barriers to safety within organizations, managing the complexity of chemical processes, and effectively communicating safety protocols to all stakeholders.

- How can advancements in technology enhance chemical process safety?

- Advancements in technology can enhance chemical process safety by enabling real-time monitoring of process conditions, predictive analytics for identifying potential hazards, automation of safety systems and controls, remote operation and maintenance of equipment, integration of safety data with enterprise systems for better decision-making, and the development of innovative safety solutions such as safer chemical formulations and materials. These technological advancements help organizations proactively manage risks and improve overall safety performance.